Hydraulic Solenoid Valves are found in a variety of equipment, from industrial to agricultural. These valves open and close depending on the direction of pressure being applied to them. If you own equipment or a piece of farm machinery, chances are you’ve experienced the frustration of mis-closing a hydraulic solenoid valve. If not, this article will help you understand what they are, where they’re used and how to use them safely.

What is a hydraulic solenoid valve?

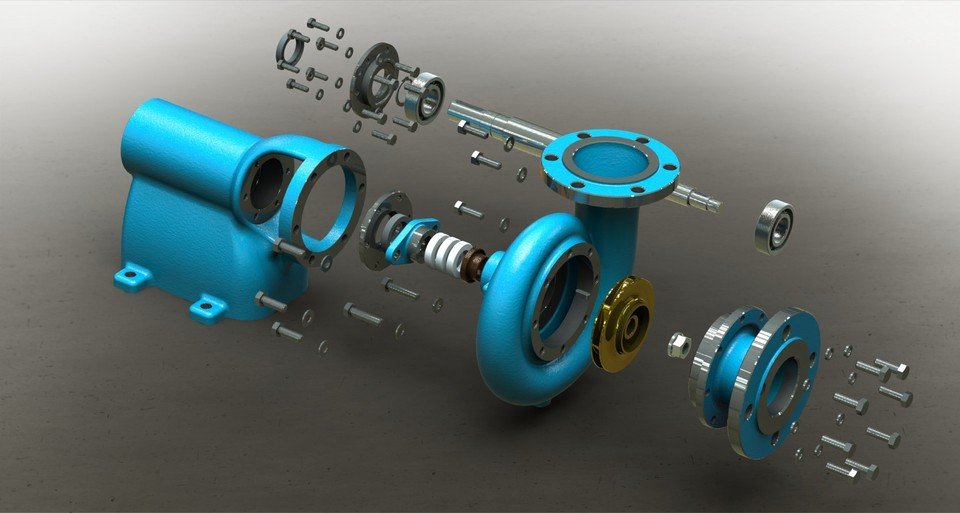

A hydraulic solenoid valve is a kind of button-activated valve that relies on pressure to operate it. When the pressure within the barrel of the valve rises, the solenoid in the valve causes the piston to move forward, which, in turn, propels the needle valve cams through the open position. When the pressure within the barrel falls, the opposite happens, which, in turn, causes the piston to move backward and retract the needle cams. The operation is similar to all the other types of Hydraulic Power Packs. These types of valves can be found in a number of equipment, from industrial to agricultural. These valves open and close depending on the direction of pressure being applied to them. It comes in a variety of types, each with its own uses and advantages.

What kind of equipment can use hydraulic solenoid valves?

Any equipment that uses pressurized fluids, such as a water pump, oil pump, or irrigation pump, can use a hydraulic solenoid valve. These are often used to control the flow of water or other fluids and can also be used as switches to shut off power to a machine or piece of equipment.

Which Types of Hydraulic Solenoid Valves You Can Use

There are 2 common types of hydraulic solenoid valves, the pushrod and the cable-driven. Both types are designed to operate with a pushrod, which looks like a tube with a bend in it. The pushrod is connected to the machine via a flexible or fixed conduit. These are found in bulkheads, valves, shutoff valves, and more.

What can go wrong when using a Hydraulic Solenoid Valve?

The most common scenario that comes to mind when thinking of potential problems with hydraulic solenoid valves is misalignment. If the pilot valve is located too close to the master control valve, the pressure in the machine may not be high enough to activate the switch. This may result in valve overload, sticking valves, or other mechanical damage. Another potential problem is valve spring loss. This can occur because the valve is designed with a light spring or because the customer doesn’t secure the valve properly. If this happens, the valve will gradually lose pressure, and you’ll need to replace it.

Conclusion

Hydraulic solenoid valves are found in a variety of equipment, from industrial to agricultural to home gardens. These valves open and close depending on the direction of pressure being applied to them. If you own equipment or a piece of farm machinery, chances are you’ve experienced the frustration of mis-closing a hydraulic solenoid valve. If not, this article will help you understand what they are, where they’re used and how to use them safely.